Front Turning Tools

Our cumulative experience of more than 40 years has showed us that every company suffers with one common problem, Burrs. When you drill holes, there are a lot of burrs. And then you deburr those holes with hand tools. We have developed patented plunge-type tools for finishing your holes, so that you can manufacture burr-free components without any off-line process starting at 1.45mm diameter. Check out our Complete Range of Deburring and Chamferring Tools.

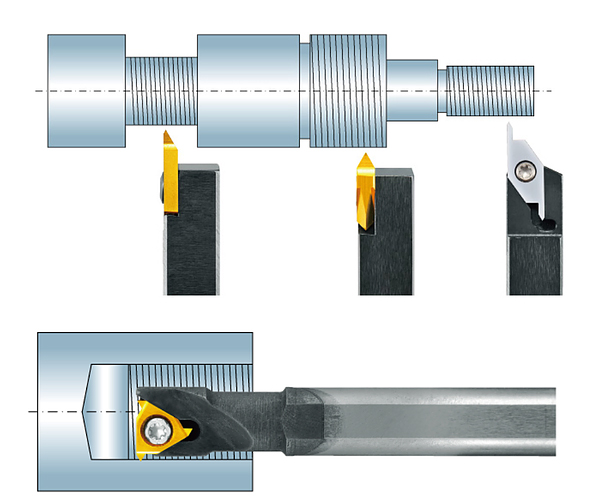

Back Turning Tools

Our heavy-duty back turning tools can provide stable machining, even with heavy depth of cut operations. Moreover, the 3D chipbreaker manages chip direction very well, giving a very good finish on OD and Face in just one pass. The best results are obtained with our through coolant tool holders. We also have standard Y-Axis through coolant tool holders for managing the most difficult chips.

Cut-off Tools

With excellent rigidity and sharpness, our cut-off tools are a best-seller in the Swiss market. Moreover, our 3D chip breaker which is newly added to parting inserts helps to control the chips extremely well. Our tools can cut up to 45mm material with insert width starting from 0.5mm. Moreover, our through coolant range of parting tools helps improve the chip control even further.

Grooving/Side-turning Tools

Our grooving range comprises all application like OD grooving, ID Grooving, Face Grooving, ID Face Grooving and Groove-Turn operations. With our range starting from 0.3mm width, our unique grooving solutions will solve even your most difficult applications with great ease.

Threading Tools

Our side-clamped threading inserts are rigid and produce good quality threads in lower times. Various line-ups are available for each specific threading operation. With our micro-grain carbide inserts offering superior wear resistance and toughness, almost all materials are readily machined by our tools.

ID Tooling

We offer through coolant boring bars and sleeves for ID operations. Our wide range of tooling consists of a large variety of ID tooling inserts, bars for ID boring, ID back turning, ID grooving and ID threading to use with the boring bars and sleeves. The sleeves come with an overhang adjust mechanism that allow you to index the bars without any height adjustment. The boring bars start from bore diameters as small as 5mm.

Rotary Broaching

Are you in the aerospace or the fasteners industry and take a lot of time making the head of the fasteners. Is it square, hexagon, splined, ribbed, or some other peculiar shape? Try our rotary broaching technology to reduce your cycle time for making such shapes down to seconds. Witness the technology for yourself in the adjoining videos.

Thread Whirling Tools

Compared to any competitor in the market, we can provide much superior thread whirling systems for a variety of Swiss-type machines. Be it a double lead thread or even a multi-lead thread, we take your challenge head on. We are experienced with tooling for bone screws as well as worm gears. Check out the videos of our thread whirlers.

Micro Drills and Micro Endmills

Our high quality micro-drills and micro-endmills, Made-in-Switzerland, provide the highest life in the industry with superior reliability. Our range of different proprietary coatings help us provide improved chip control and a wide application range. Our range starts from as small as ø 0.1 mm with increments of 10 microns and is available up to configuration of L/D ratio 12.