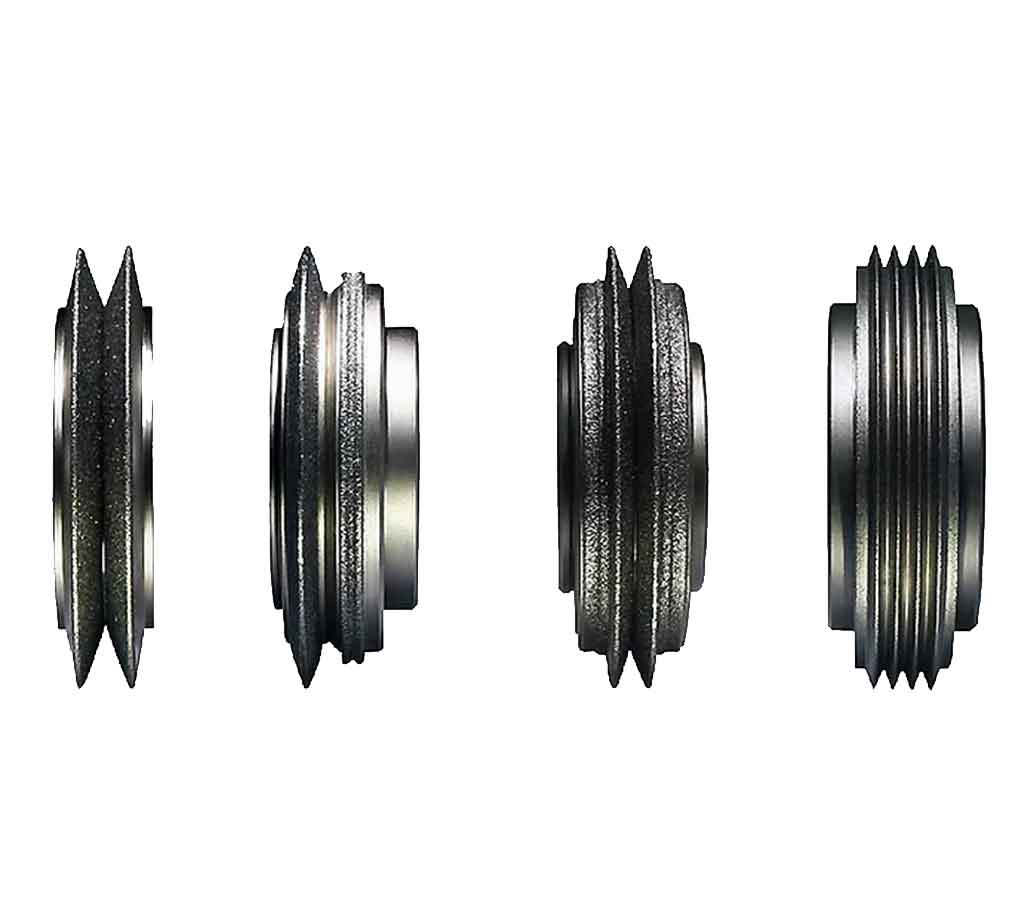

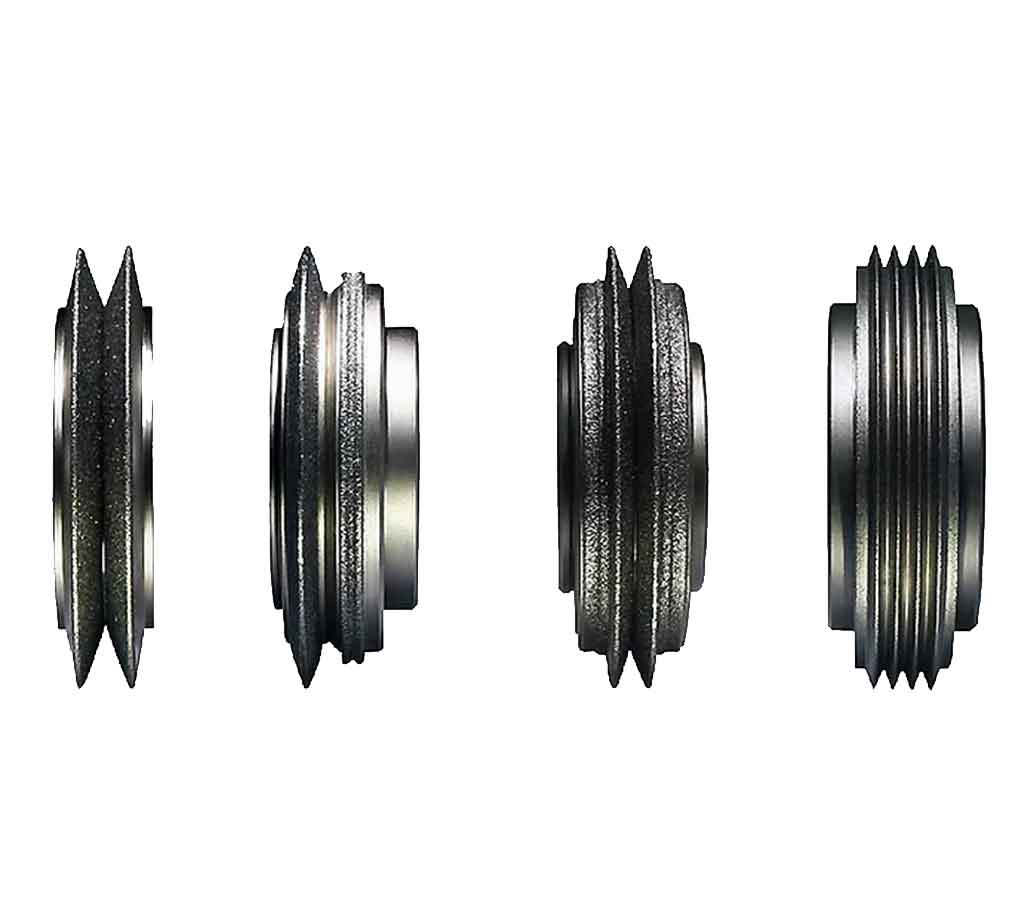

Diamond roller dressers and Gear Dressers are used for forming and dressing conventional abrasive grinding wheels and CBN wheels. Our dressers are available in electroplated-type, reverse-plated-type as well as sintered-type. We provide industry’s shortest lead time of 4 to 6 weeks for duty paid delivery at your premise which is less than half the lead time compared to 16 weeks committed by competitors. Thus, we help you get more competitive by reducing your NPD lead time.

We have supplied the world’s largest vitrified CBN crankshaft grinding wheel, for marine crankshaft grinding. Our CBN/D vitrified and resinoid abrasives are a proof of our excellence in the field. Be it CBN crankshaft grinding, CBN camshaft grinding, Diamond Tool Grinding Wheels or any special application, we have complete solution for you. We are your partners of choice for the most trusted and reliable CBN Grinding Wheels..

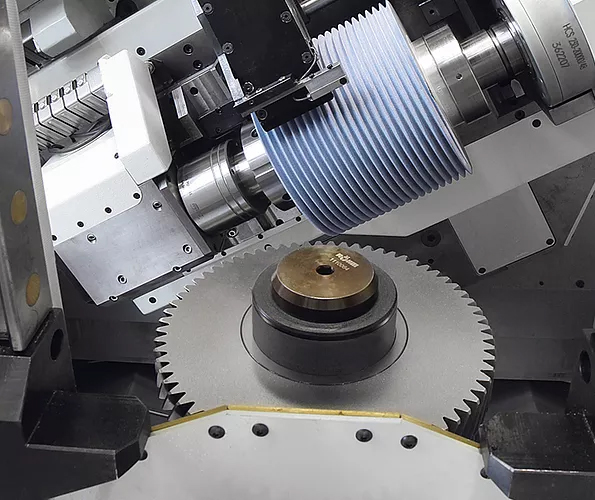

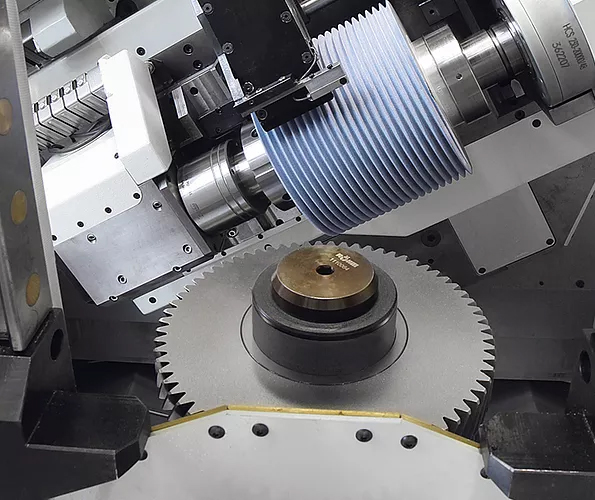

Our Gear Profile Grinding wheel have been appreciated throughout the Indian industry for our quality as well as life. Our expertise in gear making solutions is second to none. Machenzzo is a global leader in Ceramic Gear Grinding Wheels or Gear Grinding Worms for high high speed gear grinding.

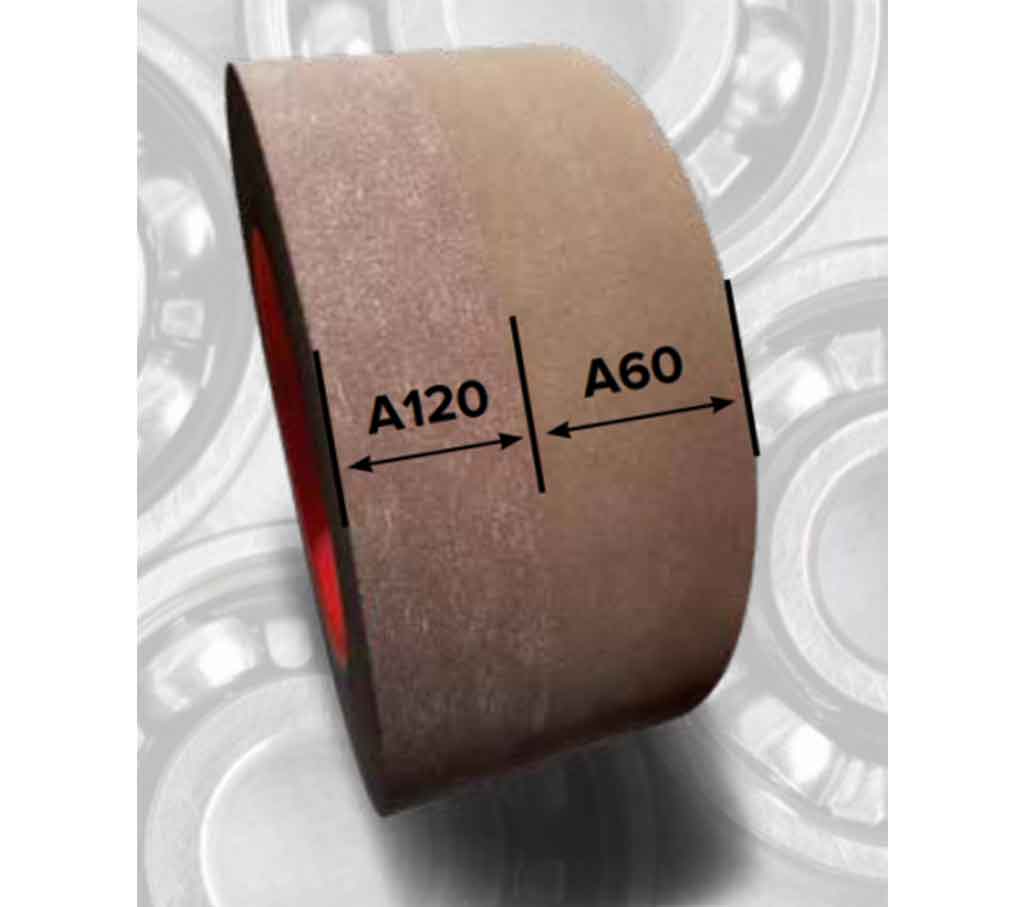

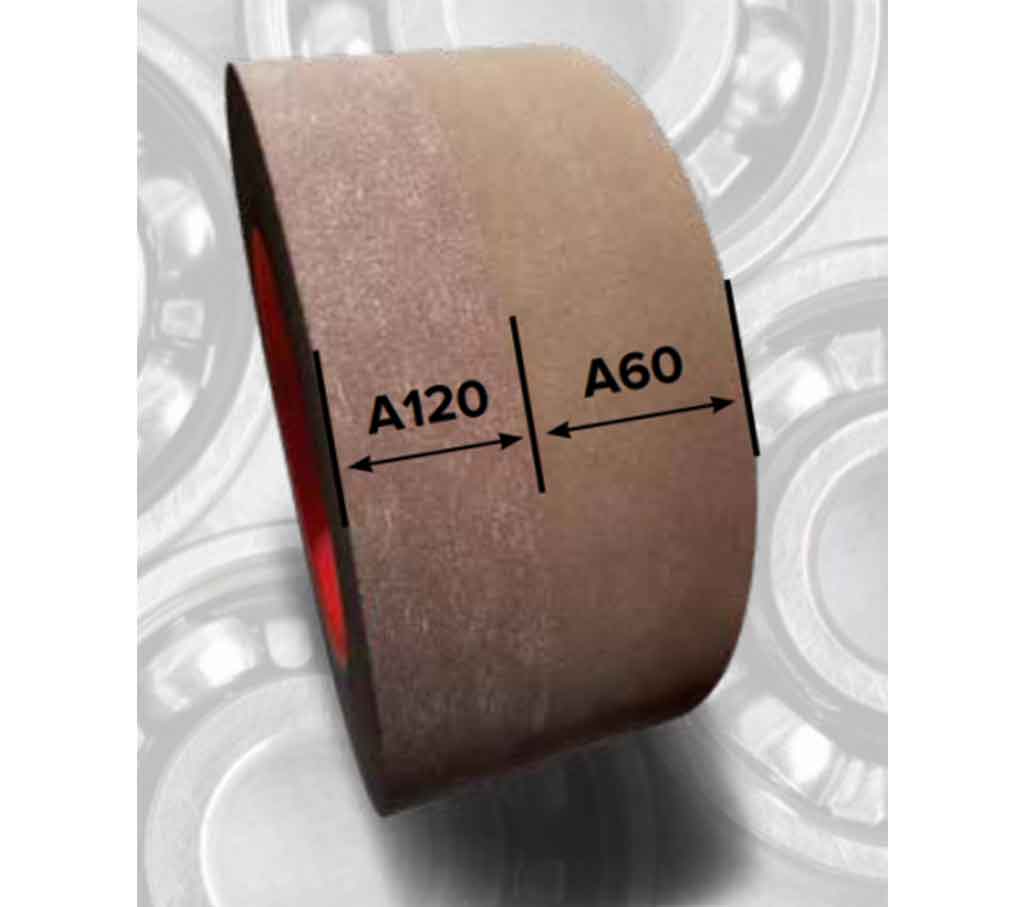

Why pay for two wheels when you can get the job done with only one?! Our dual-specification wheel allows you to grind your parts to the needed dimensions and finish tolerances faster and more efficiently.

Centerless Grinding Wheel for the Bearing Industry – Rough and Finish Dual Grit 2-in-1 combined wheel.

For your applications of large diameter cut-off wheels, we specialize in cut-off wheels of sizes greater than 400mm diameters and are India’s largest suppliers of such grinding wheels.

Whether precision, tool life quantity, rationalization effects – with our honing tools you realize your objectives in every respect. Be it track honing, bore honing or flat honing, we provide the industry’s leading honing tools for cross hatch and plateau finish in the shortest lead times in the industry.

Our superabrasive micro-grinding wheels of CBN and Diamond start from 0.5 mm diameter and are available for various applications like ID grinding, surface grinding, cutting discs, cup wheels, etc. With Swiss-precision and quality, our wheels will bring the best tool life possible for your micro-grinding applications like syringes and other medical technology applications

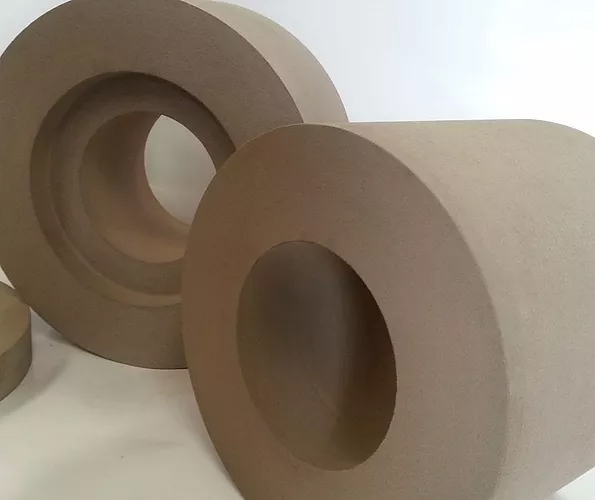

Our Rubber Control/Regulating Wheels are specially made for Center-less grinding so as not to compromise the finishing degree obtained with the wheel. These regulating wheels are very hard and wear resistant even through exercising an excellent driving action. They are designed to work for both Plunge & Creep Feed applications.

This website uses cookies to improve your experience. We\'ll assume you\'re ok with this, but you can opt-out if you wish. Read More